100kg Suction Cup Manipulator Arm Heavy Load Handling Machine Bags Suction Crane Production Line Automatic Manipulator Lifting Equipment

Overview Package Size 350.00cm * 220.00cm * 120.00cm Package Gross Weight 500.000kg GENERAL INTRODUCTION The industry ma;

Overview

PARTS AND STRUCTURE

Main Parts of Manipulator

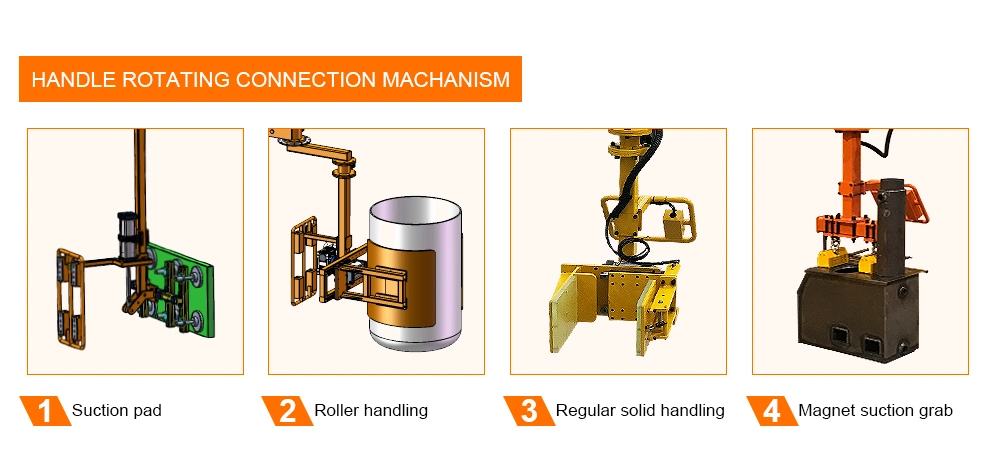

1. Column2. Cylinder3. Air Tank4. Control Box5. Handle 6. Tooling Structure7. Joint Brake

Manipulator with Rigid Arm: The advantage of this manipulator is that it will achieve more precise position and angle control, which is suitable for situations where the accuracy of the installation position is relatively high Manipulator with Cable: The advantage of the soft cable structure is that it is more flexible. It is suitable for situations where the installation position and angle are not strictly required and manual fine-tuning is required.

INSTALLATION WAY

WORKING SCENARIO

Basic Info.

| Certification | ISO |

| Control Mode | Continuous Path Control |

| Drive Mode | Pneumatic |

| Condition | New |

| Application | Load |

| Main Component | Power Arm, Fixture, Control System, Security Syste |

| Max Height | 3500mm, Customized |

| Basic Design | Grasping, Carrying, Lifting, Rotating |

| Iinstallation Form | Ground Installation, Customized |

| up and Down Stroke | 0-1600mm, Customized |

| Working Radius | 2500-3000mm, Customized |

| Capacity | 100kg, Customized |

| Type | Power Assisted Manipulator, Gripper Robot |

| Transport Package | Wood Box |

| Specification | Customized |

| Trademark | Escott |

| Origin | China |

| HS Code | 8428909090 |

| Production Capacity | 100PCS/Month |

Packaging & Delivery

Package Size 350.00cm * 220.00cm * 120.00cm Package Gross Weight 500.000kgProduct Description

GENERAL INTRODUCTIONThe industry manipulator is a set of assisted handling equipment designed based on dynamics and ergonomics, and its operation mode is through manual button operation, by the gripping of the fixture tooling to achieve the transfer action of the object.

The general application scenarios mainly include:1. The target object is too heavy or too large to achieve manual handling2. The transfer angle and position of the target object are difficult to achieve manually3. The target object is easy to cause high loss through manual transfer4. The target object is easy to cause large manpower lossBased on the above situation, we introduced the robot as an auxiliary handling tool to solve the problem perfectly. In this process, irregular objects, heavy objects, and special objects have achieved efficient transfer, saving and protecting manpower loss, and it's been more and more widely used in the industrial production process.PARTS AND STRUCTURE

Main Parts of Manipulator

1. Column2. Cylinder3. Air Tank4. Control Box5. Handle 6. Tooling Structure7. Joint Brake

Manipulator with Rigid Arm: The advantage of this manipulator is that it will achieve more precise position and angle control, which is suitable for situations where the accuracy of the installation position is relatively high Manipulator with Cable: The advantage of the soft cable structure is that it is more flexible. It is suitable for situations where the installation position and angle are not strictly required and manual fine-tuning is required.

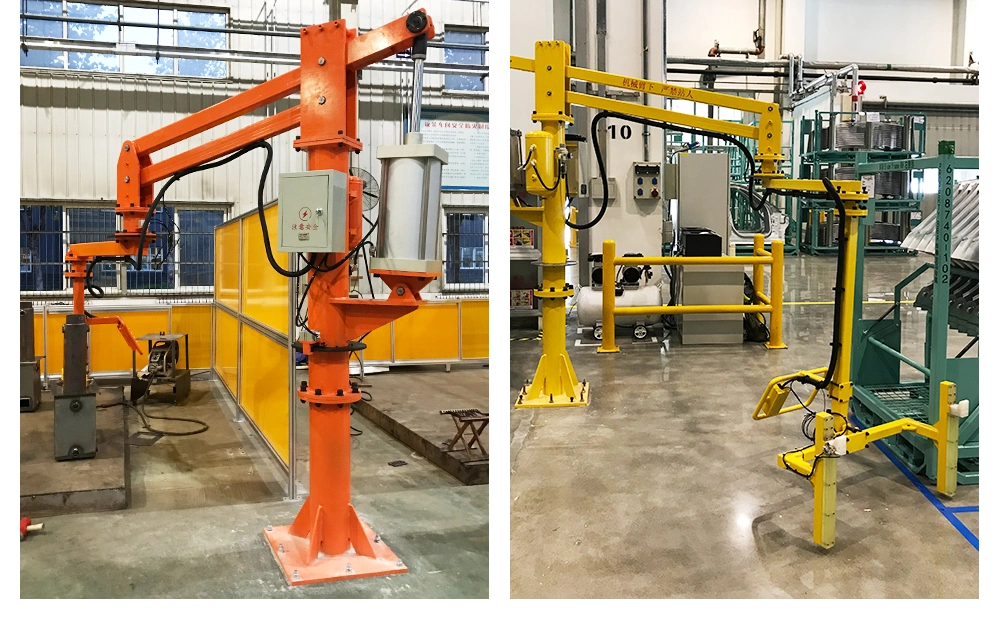

INSTALLATION WAY

- Fixed Column

- Movable Column

- Fixed Overhead (Wall installation)

- Running Overhead (by Sliding trolley)

| Model No | Design Struture | Design Drawings | Lifting Height | Radius | Capacity | Fixing Method | Link |

| ES-50RS-QH | with Soft Cable | 2500mm | 2500mm | 50KG | Fixed Column | ||

| ES-60YB-QD | Rigid Arm | 2800mm | 3000mm | 60KG | Movable Column | ||

| ES-100RS-TS | Folded Arm with Soft Cable | 3000mm | 3000mm | 100KG | Fixed Column | ||

| ES-200KG-YB | Rigid Arm with Suction Pad | 3400mm | 3500mm | 200KG | Fixed overhead | ||

| ES-300KG-MYB | Rigid Arm | 3000mm | 2500mm | 300KG | Movable overhead | ||

| ES-150KG-FLD | Flexible Design | 1500mm | none | 150KG | design with forklift |

WORKING SCENARIO

You may also like

Send inquiry

Send now