Stationary Fixed Warehouse Hydraulic Automatic Unloading Dock Leveler Equipment for Loading Bay

Basic Info.

| Model NO. | LESHO-Leveler |

| Lift Mechanism | Hydraulic Power |

| Carrying Capacity | 6t,8t,10t,15t |

| Moves | Stationary |

| Driven Type | Hydraulic |

| Running Mode | Fixed |

| Feature | Explosion-Proof |

| Certification | CE, ISO 9001 |

| Color Customize | Ral Color Available |

| Protection Class | IP55 |

| Working Temperature | -35 to 65 Celsius Degree |

| Power Supply | 220V 50Hz / 380V 50Hz |

| Standard Size | L2000*W2000*H600mm (Customized Available) |

| Transport Package | Wooden Package |

| Specification | 6000kg-15000kg |

| Trademark | LESHO |

| Origin | China |

| HS Code | 84254290 |

| Production Capacity | 50000sets/Year |

Packaging & Delivery

Package Size 210.00cm * 210.00cm * 65.00cm Package Gross Weight 1000.000kgProduct Description

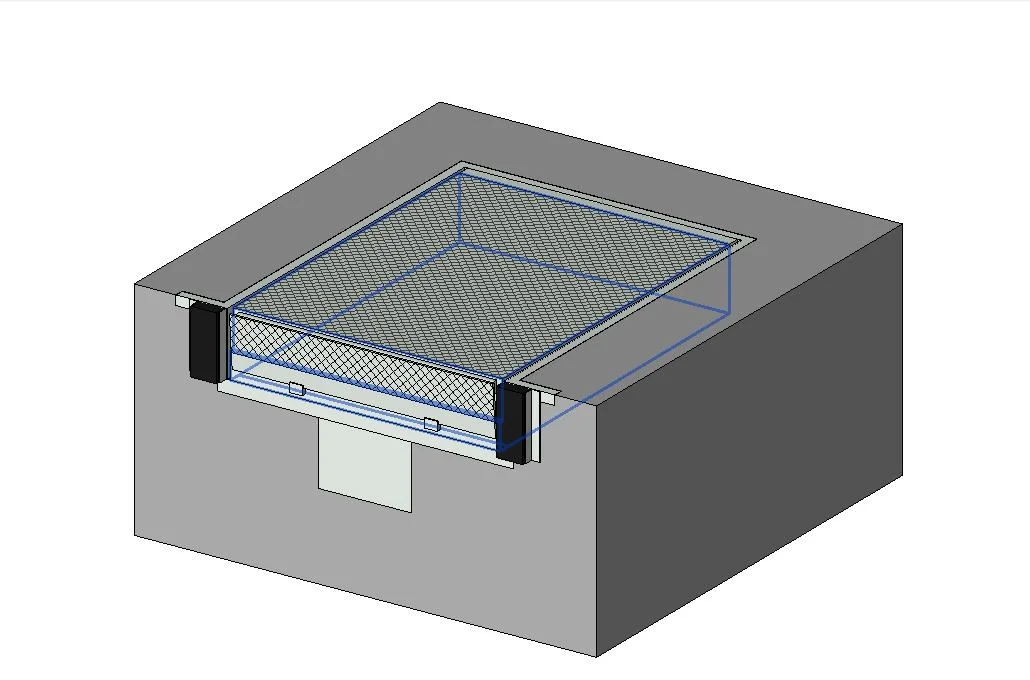

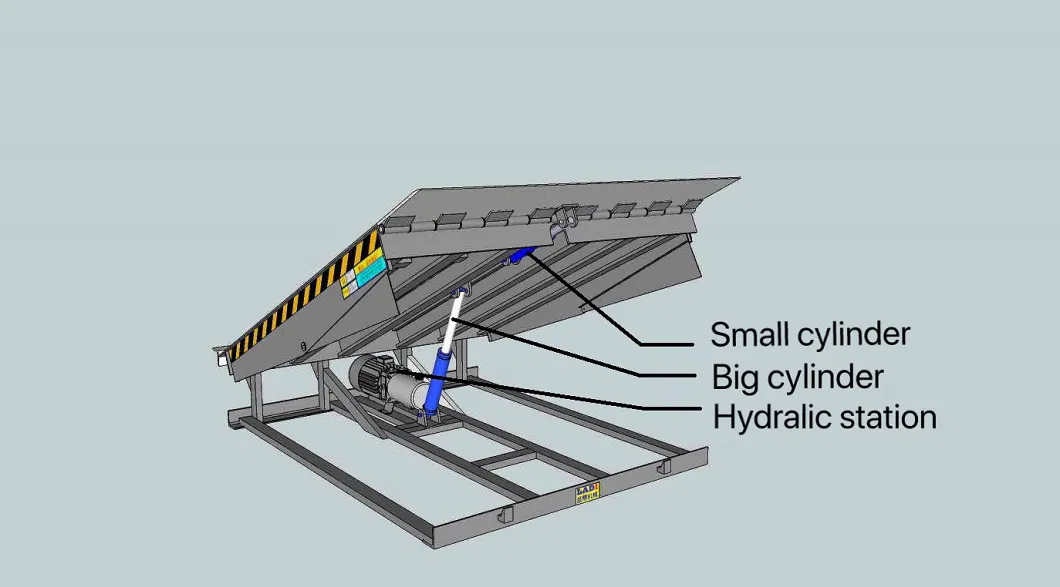

Automatic Stationary Fixed Hydraulic Dock Leveler or Dock Ramp:

Application:

The dock leveler is the best solution to adjust the height difference between the loading platform and the container truck.the height can be adjusted arbitrarily, the adjustment range is large, the loading and unloading efficiency is improved, and the manpower is saved.Widely used for large enterprises with frequent loading and unloading vehicles and different vehicle models, warehouses, stations, docks, warehouse logistics bases, postal transportation, logistics distribution, etc.

Loading capacity and Type Selection:6000 kg,8000kg ,10000kg ,15000kg .

| Dynamic load | Panel thickness | Panel reinforcement | Thickness of mouth plate | Base frame | Static load | Use forklift range |

| 5tons | 6mm | 4mmL steel | 12mm | 60 channel steel | 8 tons | 2.5 tons plug-in |

| 8tons | 8mm | 4mmL steel | 16mm | 100 channel steel | 11tons | 3.5 tons plug-in |

| 10tons | 8mm | 14 # I-beam | 16mm | 100 channel steel | 13tons | 5 tons plug-in |

| 14tons | 10mm | 16# I-beam | 16mm | 100 channel steel | 17tons | 6 tons plug-in |

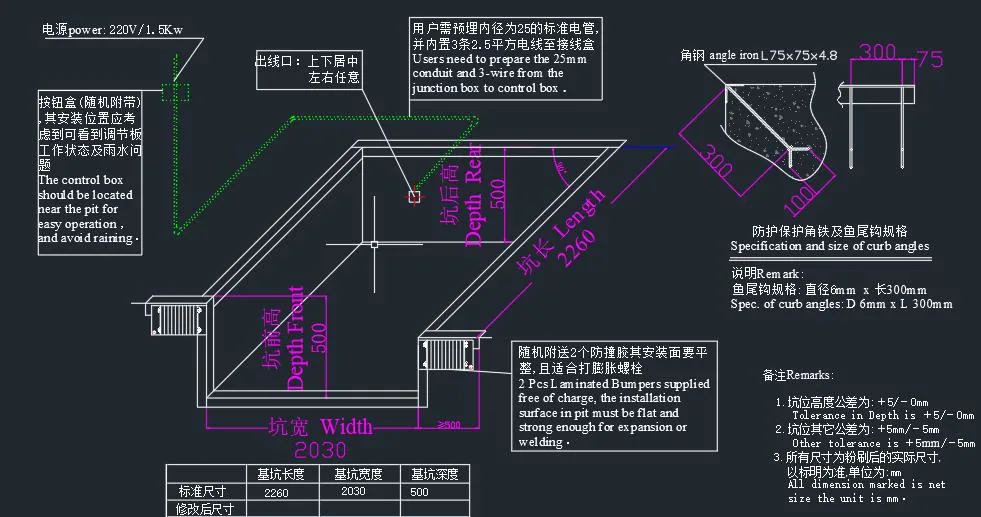

CAD Drawing :

Accurate shop drawing to show the pit dimension clearly, make sure there is no misunderstanding ,and the pit construction is accurate.

Width=1830mm, Length=2000m, Height=500mm;

Width=2000mm, Length=2000m, Height=500mm;

Width=2000mm, Length=2500m, Height=500mm;

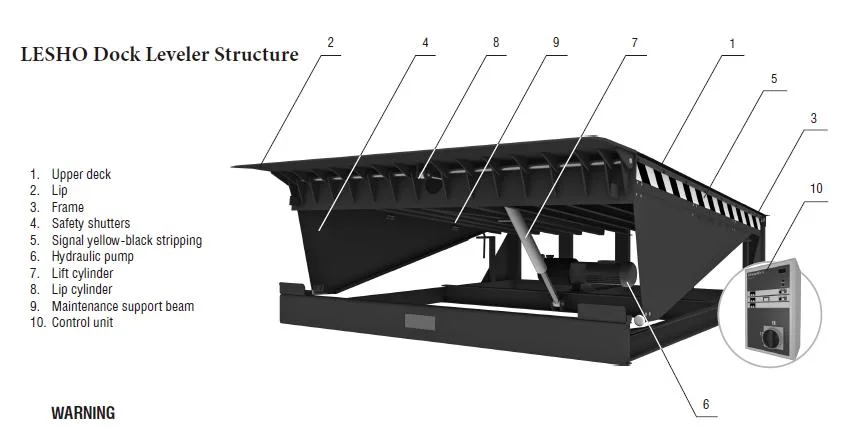

Main Platform:

1. Surface sheet:6mm-8mm thick completely whole set steel plate according to loading capacity;

2. Whole-piece steel sheet, rather than welded joined sheet like competitors, with much higher strength and work life;

3. Underneath support: high-density steel tube or C-channel to support the surface sheet.;

4. Surface treatment: blasting and powder coating, with high rust proof performance

Top Lip:

1. Material: 12-16mm thick steel sheet;

2. Surface treatment: blasting and powder coating. Special embossed treatment, to make it antiskidding and improve the safety of forklifts passing.

Hydraulic Motor:

1. Power supply :3-phase 380V/50Hz

2. Output power:0.75KW-1.5KW;

3. Top China brand or Italy brand;

4. Overheating self-protection function.

Control Panel :

1.Multiple-function controller, with three functional parts:

2.Operation button: press one time, the whole procedure started until finish;

3.Power-switch button: switch off power easily when necessary, like work-off, daily maintenance, or repairing;

4.Emergency stop button: it can stop the dock leveler immediately when.there is something emergency. This can help protect workers and avoid accidents;

Dock Bumper:

1. One pair for each dock leveler;2. Wear-proof high-strength rubber material;3. To be fixed onto concrete with expansion bolts.

Welding Robot make the welding work more accurate:

Our Dock Leveler Features:

1.The overall assembly can bear 120% load of standard nominal load capacity. Under static pressure of 24 hours,the deformation is within 3mm. And after pressure released , the deformation will recover.2. Platform ground is made from high-strength 8mm or above thick steel plate. Surface is processed with groove mil-ling to make it anti-skid.3. Hinge and Shaft , are Super-High-Temperature heat treated, to reduce its deformation4. Whole set of hydraulic drive station is imported from Europe, with stable power output. It can work under high fre-quency because of very low work temperature of oil. High standard seal avoids oil leaking.5. Surface treatment:Coated with epoxy resin paint, very durable and high anti-corrosive.6.Blue, Grey, Green, or customized

We supply whole set Complete Loading Bay or Dock: (Dock Leveler ,Sectional Door ,and Dock shelter )

Loading Bay is a complete assembly of Overhead Door, Dock Leveler and Dock Shelter&Seal.It is widely seen in wareh-house, factory, and logistics industry. These three parts work together to improve loading efficiency and protect indoor enviroment.

Loading and packing Process :

Standard size :L2000*W2000*H600 mm ,one 40 feet HQ container can load 20 sets dock leveler.One 20 feet container can load 8 sets dock leveler.

Our Company profile

Our Certification :

Our Exhibition :FAQQ Why choose us ?

A:- Most cost effective products (Best Bulk Price with stable quality.)

- Professional Technical sales support pre sale work also the after sale work.

- More than 20 years experience on the production and customization ,

- More than 10 years export experience ,reasonable shipment arrangement,and fast delivery ,save time is save money

Q How can we get start the first?

A. We only need your basic background information and the project site information.If there are drawings to show your factory site plan will be best.We can provide whole set completely solution for you based on these information .Q What about the installation?

A For all of our products ,we will provide the clearly installation manual and video ,also make description installation precautions documents ,make sure even you do not have experienced workers, you can also install the door by your own worker.For the complex big project ,we will send our engineer to site guide for the installation.Q Which kinds of payment you accept?

A We usually accept T/T in advance, L/C for large sum, West Union, etc. If you prefer other payments terms, please feel free to contact us .Q How long is the lead time ?

A 7-10 days for production ......

Q How about the factory tour ?

A We are very welcome for your visit .We have office ,showroom ,and warehouse in Shanghai ,Our own factory is in Zhengzhou City,Henan Province .We also have more than 80+ partner factory In Wuxi,Suzhou,Changzhou and so on .

Q How about the after sale service?

A Spare parts will be delivery out within 24 hours by DHL ,UPS ,TNT and so on .

Q Can we become your agent ?

A Yes ,we are very welcome new partners ,but we have to check if there is already have partners in your local area